ODE Glasswool Fibers

INDUSTRIAL BUILDING BOARD

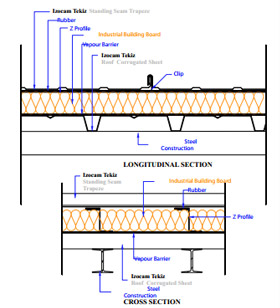

Industrial Building Board is a glass wool board faced with black glass tissue on one side. It is utilized for thermal insulation, sound insulation and fire safety in the roof cladding of industrial buildings.

Application

One layer of nylon cover is laid on corrugated metal roofing sheet as a vapour barrier. It is overlapped at the seams by 10 cm. and adhered to the surface. On top of vapour barrier layer, Industrial Building Board is placed. The application is completed by metal cladding. Applying acoustic band in front of the spacers is recommended in order to prevent sound and thermal bridges where metal pieces come in contact to each other.

Benefits

- High thermal insulation

- Fire safety

- Sound insulation

- Easy to apply

- Lightweight

Technical Data Sheet

| Properties |

Symbol |

Unit |

Description |

Tolerance |

Standard |

| Material |

- |

- |

Glass Wool |

- |

TS EN 13162 |

| Density |

ρ |

kg/m3 |

20 |

+/-10% |

- |

| Width |

W |

mm |

600 |

+/-1,5% |

TS EN 822 |

| Length |

L |

mm |

1200 |

+/-2% |

TS EN 822 |

|

Thickness |

t |

mm |

50 |

80 |

100 |

-3 or -3 %,

+10 or 10 % ** |

TS EN 823 |

| Facing |

- |

- |

Black glass tissue |

- |

- |

| Reaction to fire |

- |

- |

A1 |

- |

TS EN 13501-1 |

Declared Thermal

Conductivity (10 °C) |

λD |

W/m.K |

0,035 |

- |

TS EN 12667

TS EN 12939 |

| Thermal Resistance |

RD |

2 |

1,40 |

2,25 |

2,85 |

- |

TS EN 13162 |

Short Term Water

Absorption |

WS |

2 |

< 1 |

- |

TS EN 1609 |

Specific

Heat * |

c |

kJ/(kg.K) |

0,84 |

- |

EN 12524 |

| Dynamic Elasticity * |

Edyn |

kN/m2 |

0,8 |

- |

DIN 52214 |

| Packaging Material |

- |

- |

PE Film + PE Sleeve |

- |

- |

| Other Information |

Maximum service temperature on the side faced with glass tissue is 200 °C. |

Safety Reminders for Loading, Unloading, Shipping and Storing

- These operations should be done indoors if the weather is rainy.

- Loading and unloading should be done by (at least) two people.

- Products should be wrapped by a waterproof cover even if the shipping distance is short.

- Products should not be superposed with pallets.

- Products should not be put into upright position.

- Products should not be stepped on and should not be used as steps.

- Products should not be pulled by their package.

- Products should be in packages (10 each) and maximum 6 packages can be superposed.

- Before binding, hard cardboards (minimum 20 x 50 cm) should be put on the corners of packages to protect against possible damages by ropes.

- Storage area should be protected against any wet threats such as rain, float, etc. Indoor spaces should be preferred.

- The packages should be put on the floor with extra care so the corners of the product especially is not damaged by a hit.

Enquiry

|

|